11-14% "Hadfield Grade" Austenitic Manganese Steel Shotblast Hangers |

||

|

|

|

(Above Left) Multi-part Forging Hanger:

|

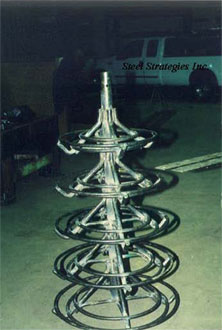

(Above Right) Spinner Hanger Fixture:

|

(Below Left) Positioning Hanger:

|

(Below Right) Monorail Hanger Fixtures:

|

|

|

|

|

|

| Foundry Shot Blast Parts Hangers:

|

|

|

|

|

|

|

|

|

|

|

Spinner Hanger Fixture:

Spinner Hanger Fixture:  Steel Multi-Part Isolation Hanger Box:

Steel Multi-Part Isolation Hanger Box:  Monorail Hanger Fixture:

Monorail Hanger Fixture: